EMS2.0 Energy Efficiency Management System

Acrel has a product ecosystem ranging from cloud platform software to terminal components. Currently, over 30,000 system solutions are in use nationwide, ensuring efficient and safe energy use for users. The company is experiencing steady growth. Adhering to the philosophy of "innovation, efficiency, unity, and integrity," the company will promote stable operations and continuous innovation, provide users with more and better solutions, products, and services, and contribute to the sustainable development of society.

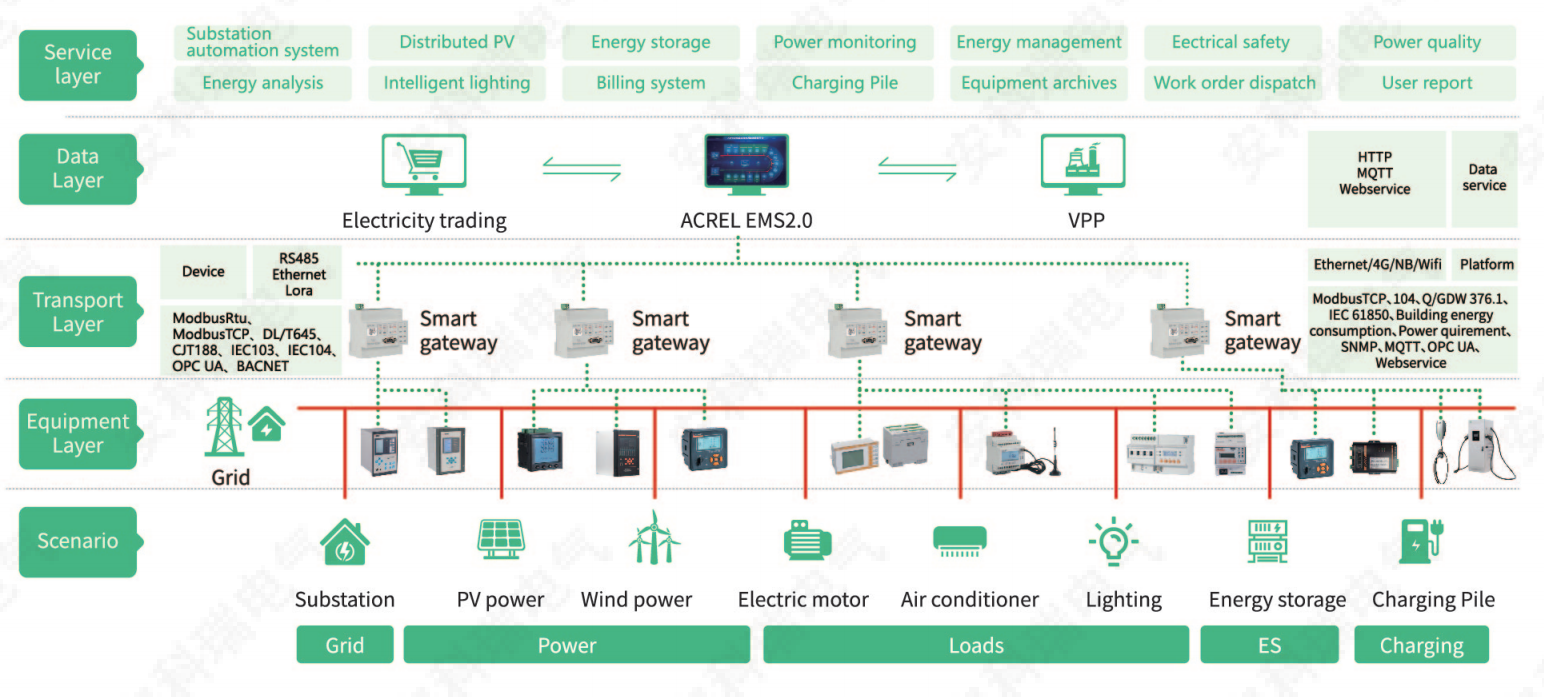

The Acrel EMS 2.0 Energy Efficiency Management Platform monitors and analyzes power, grid, load, energy storage, and charging. Optimize data interaction between individual systems to improve energy efficiency, reduce operating costs, and achieve peaking and carbon neutrality.

Various monitoring, analysis, protection, and management devices independently developed by Ankerui are installed at each key node of the source, network, load, storage, and charging system. Distributed power sources, energy storage systems, controllable loads, electric vehicles, and power routers are integrated through advanced control, measurement, communication, and other technologies. The platform flexibly adjusts the microgrid control strategy according to the latest grid prices, power loads, grid distribution instructions, and other conditions, and sends them to energy storage systems, charging piles, power routers, and other systems to ensure that the enterprise microgrid always operates efficiently and stably.

-

FULL

-

SECURE

-

VISUALLY

-

System structure

Acrel EMS 2.0 distributes and manages power, grid, loads, energy storage, and charging. Reduce costs, improve the efficiency of renewable energy use, and benefit from peak-valley arbitrage, demand management, and VPP transactions.

Advantages

-

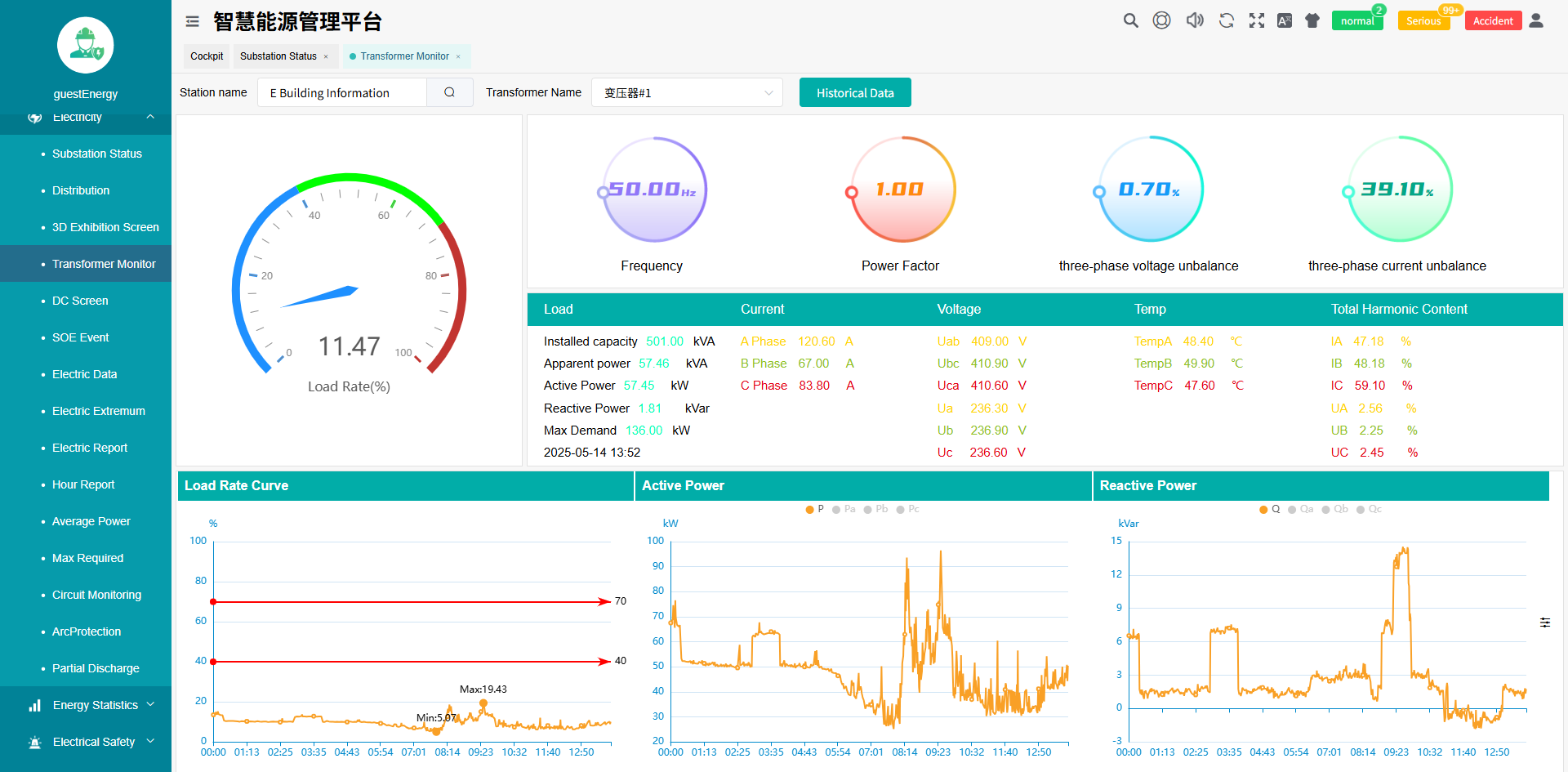

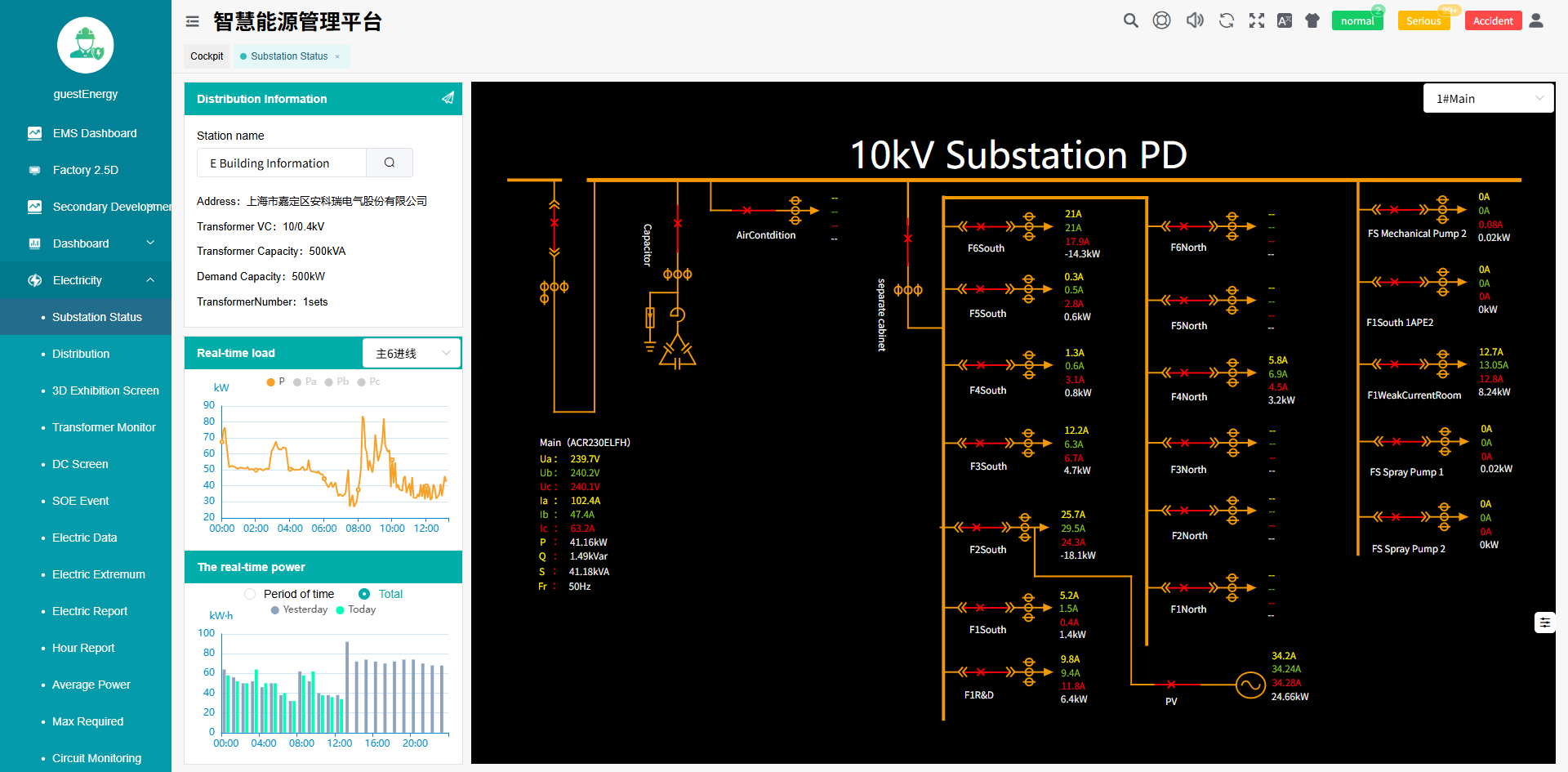

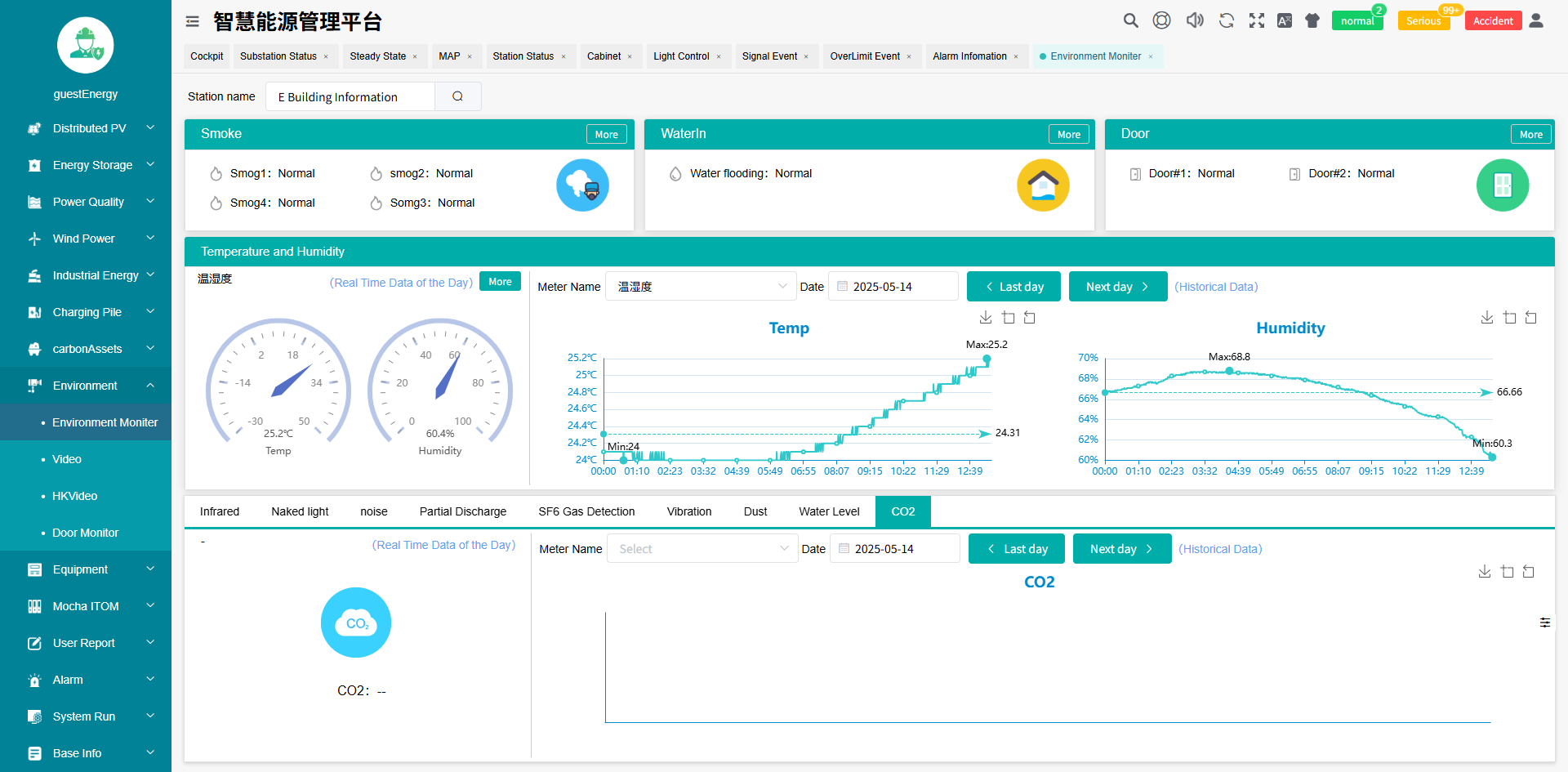

Performance monitoring:

Real-time monitoring of voltage, current, power, and other performance parameters of high- and low-voltage distribution cabinets, enabling remote measurement, remote signaling, remote control, and remote adjustment. Real-time monitoring of the temperature and humidity of each distribution room, smoke sensors, door magnets, water ingress, harmful gases, and other environmental parameters, as well as interfacing with the exhaust system when the amount of harmful gas exceeds the standard. Real-time monitoring of the operating status of key power supply and distribution equipment such as transformers, diesel generators, UPS, DC panels, etc.

-

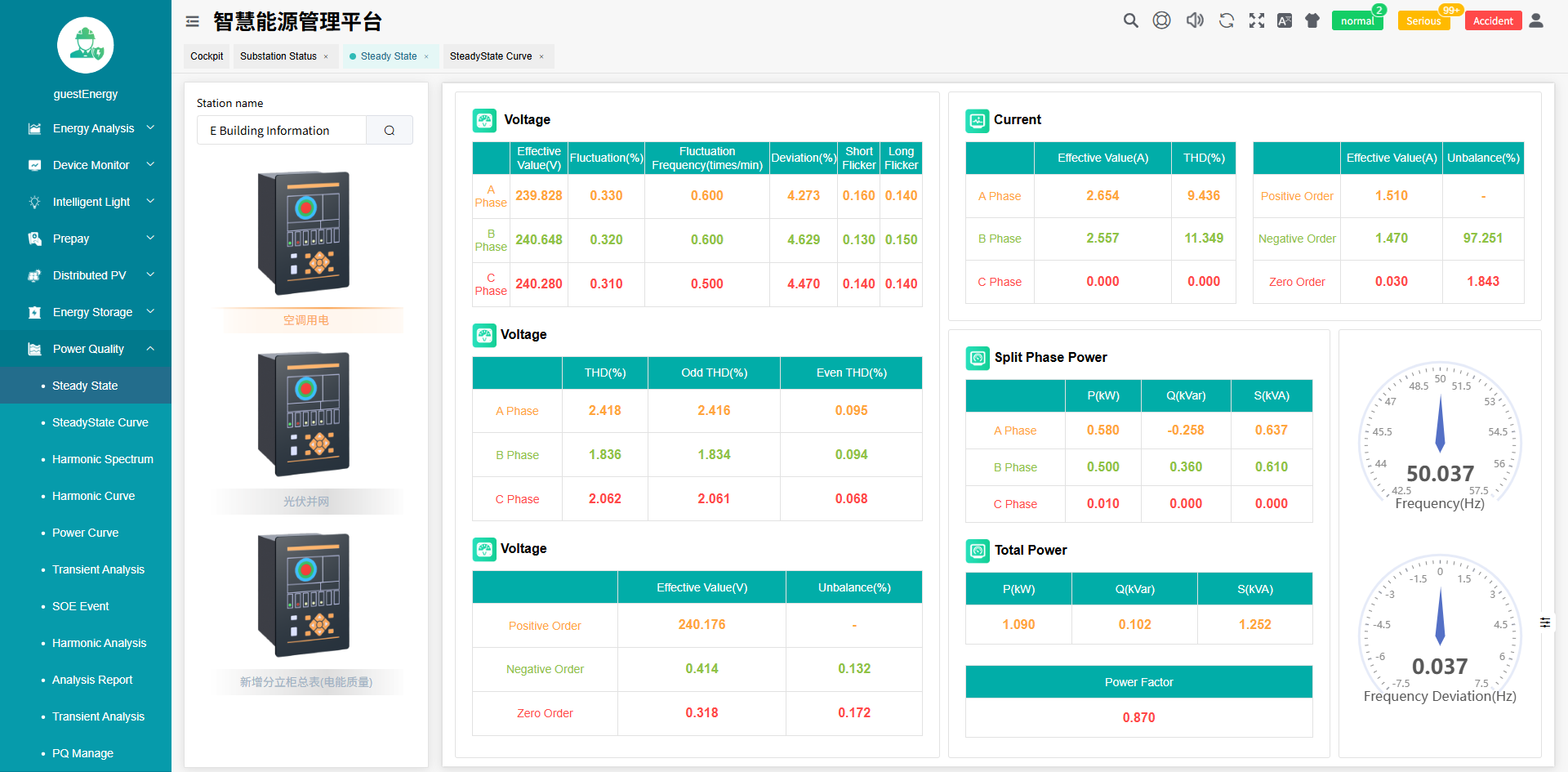

Power quality:

Monitor the power quality of each incoming line circuit, including voltage dips, transients, steady state, harmonic distortion, and other data waveform recordings. Then determine the direction of the disturbance in the distribution system and generate a power quality analysis report. Active filtering devices and reactive power compensation devices compensate and regulate power quality on the 0.4 kV side. The system monitors the operation of active filtering devices and reactive power compensation devices in real time to ensure that power quality meets production requirements.

-

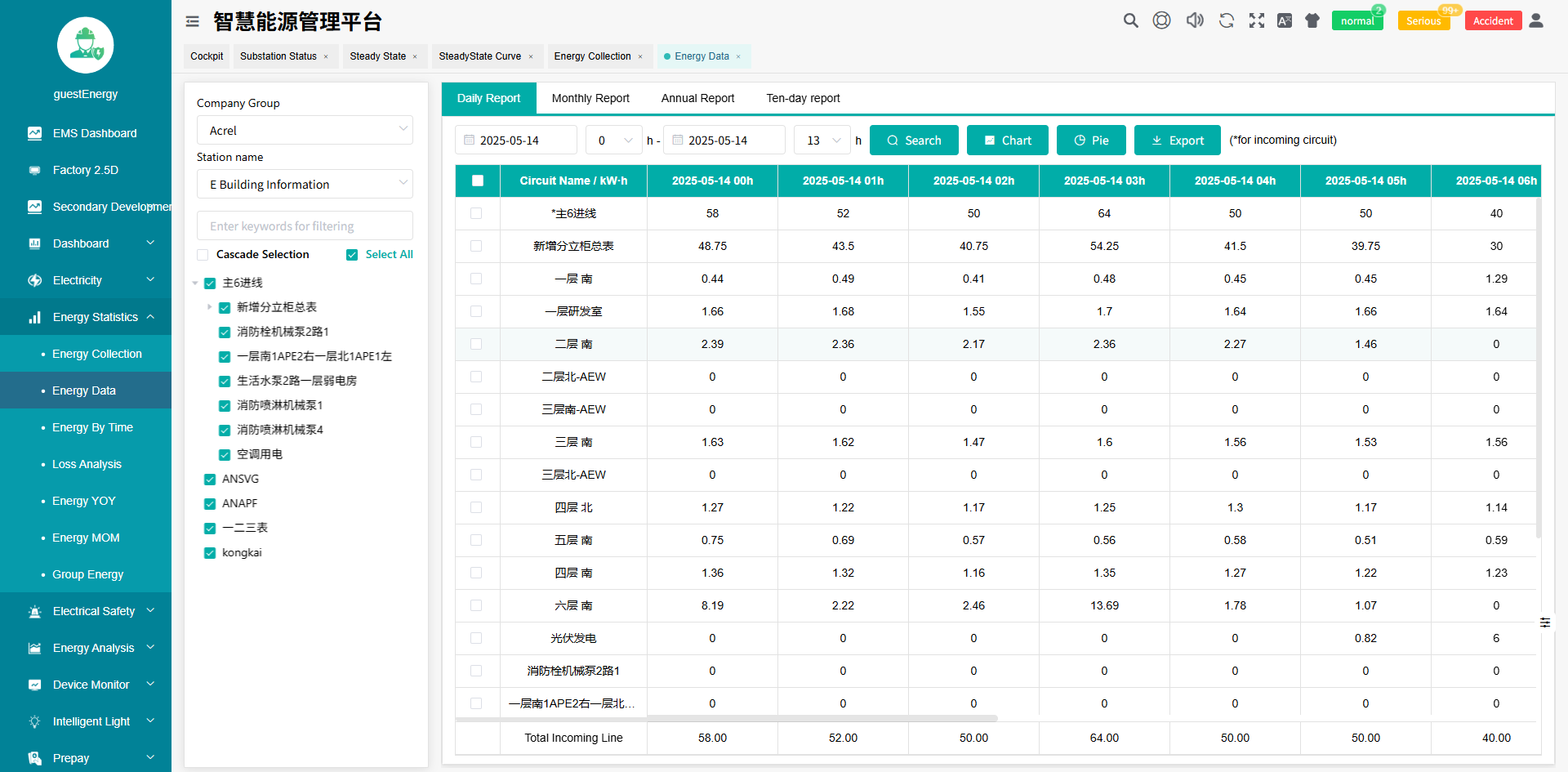

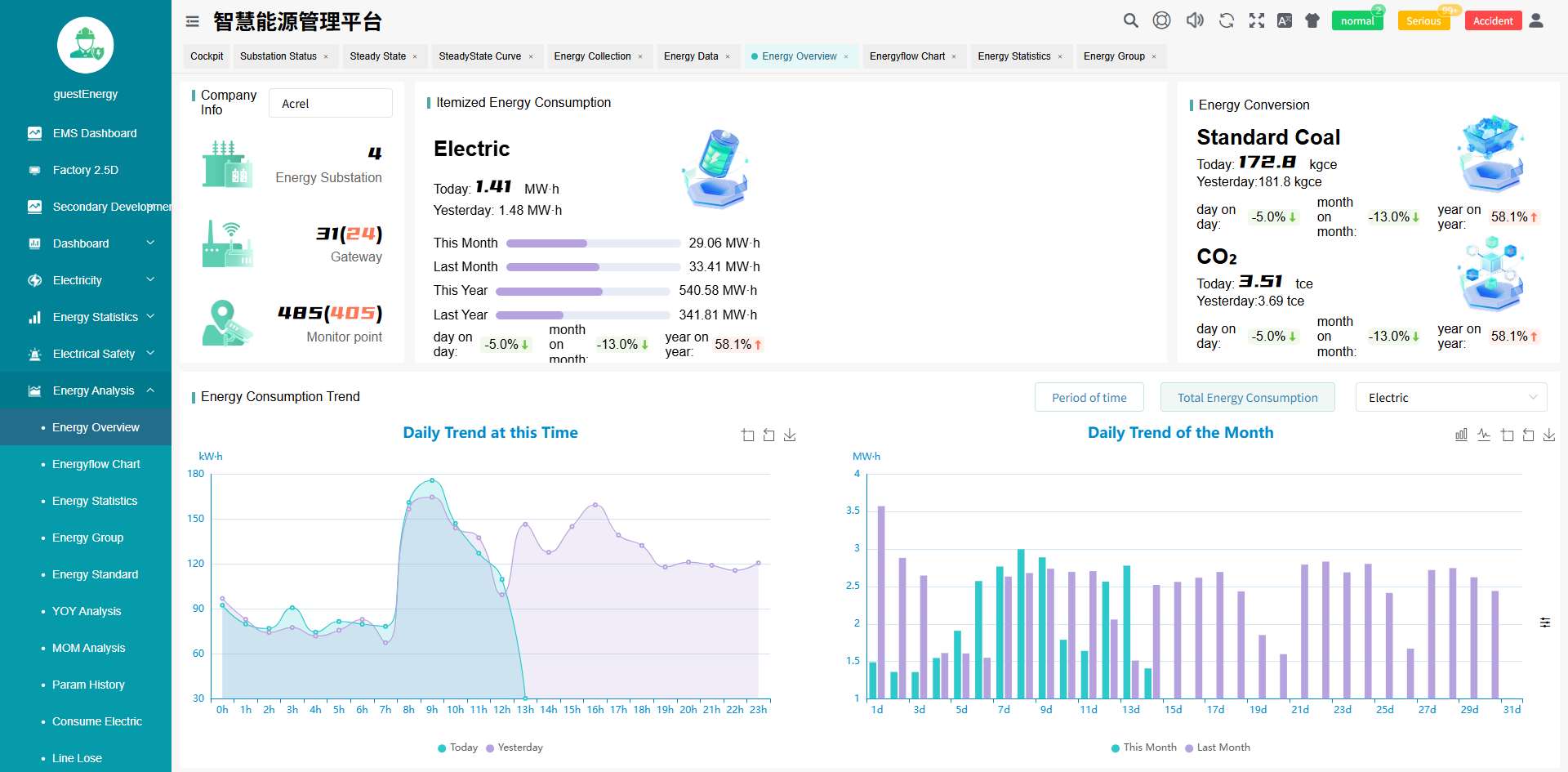

Energy statistics:

Create an energy efficiency benchmark to provide relevant comparative data for future technical improvement efforts. Fluctuations in unit consumption and energy efficiency can provide managers with a timely reminder to identify and analyze the causes of high or low efficiency and provide guidance for future efficiency improvements.

-

Energy analysis:

By forecasting energy consumption, early warnings can be provided for internal energy consumption management within the company and countermeasures can be taken in a timely manner.

-

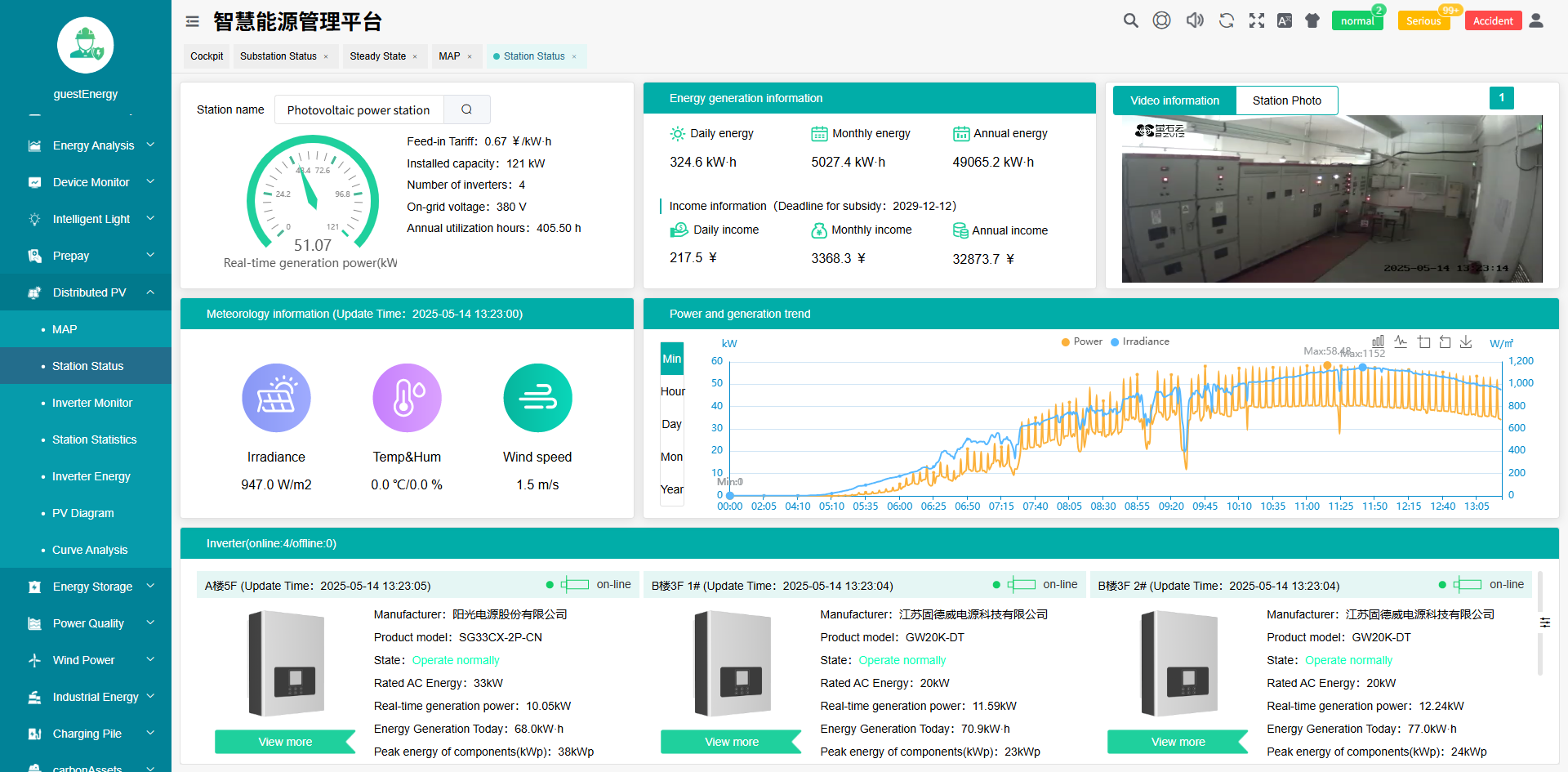

Photovoltaic monitoring:

Access the power generation data of industrial distributed photovoltaic power plants, collect data from photovoltaic inverters and grid-connected cabinets, and perform daily, monthly, annual, and cumulative revenue analysis and emission reduction analysis. Display detailed inverter data, including inverter information, real-time power generation, daily/monthly/annual power generation, revenue, power generation and power generation trend curves, DC and AC side data, and more; Real-time display of the primary circuit diagram of the PV power plant and real-time data of the DC/AC side of the PV strings.

-

Energy storage:

PCS monitoring, charge and discharge performance, and operating status; battery voltage, temperature, SOC; grid cabinet performance monitoring and power generation statistics; charge and discharge capacity, cycle count; energy storage revenue statistics.

-

Other features:

Billing system, charging station, smart lighting, user report, environmental monitoring

-

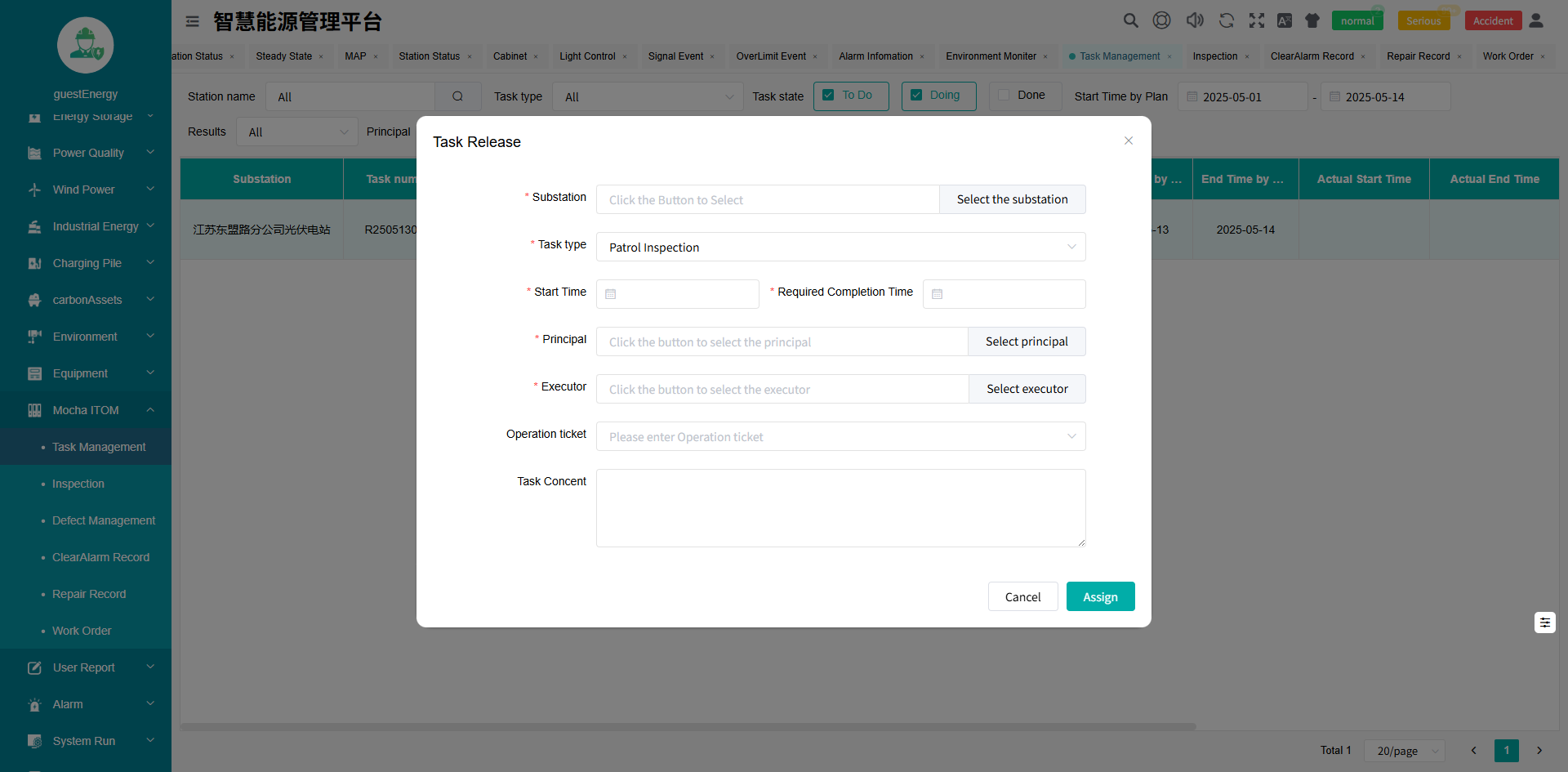

O&M task management:

Operation and maintenance function

suggested products

projects