Project background

Jiaozuo Coal Industry Group is one of the key member companies of the Henan Energy and Chemical Industry Group and boasts a 112-year mining history. Its mining area is located in the northwest of Henan Province and spans four cities: Luoyang, Jiyuan, Jiaozuo, and Xinxiang. It is one of the six major anthracite production bases in my country and one of the four largest coal mines in the country that first applied modern mining technology. Coal and electricity are the group's two main industries. Its energy business focuses on thermal power generation and also encompasses multiple areas such as power supply, heat generation and supply, renewable resource recycling, technical services, equipment maintenance, and leasing services.

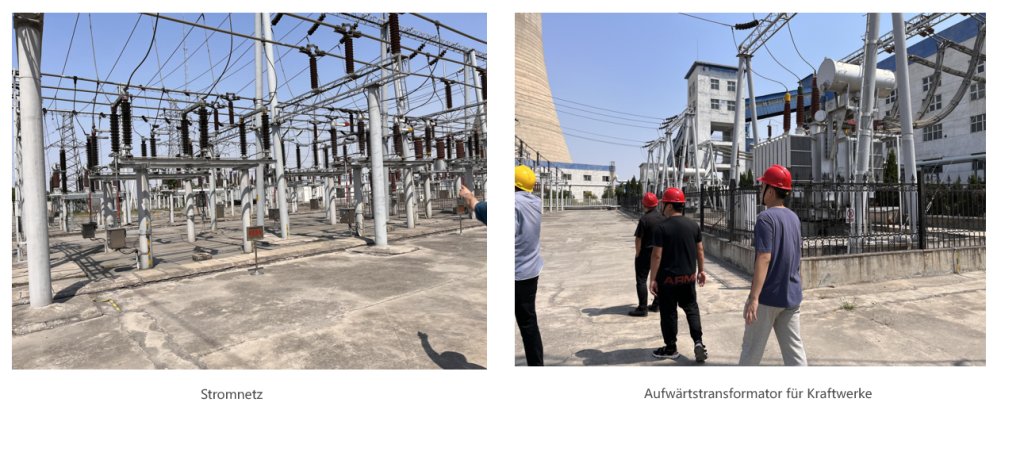

It is responsible for the installation, maintenance and testing of power equipment of 110 kV and below, and owns and manages 33 substations, including 110 kV, 35 kV and 10 kV (6 kV) substations, as well as power lines covering the three mining areas of Luoyang, Jiaozuo and Xinxiang with a total length of about 530 kilometers.

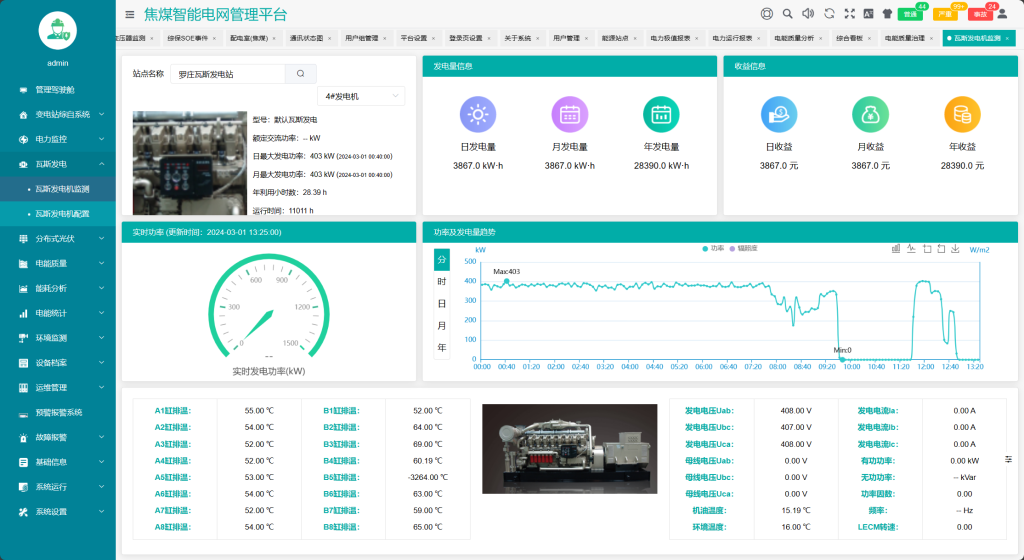

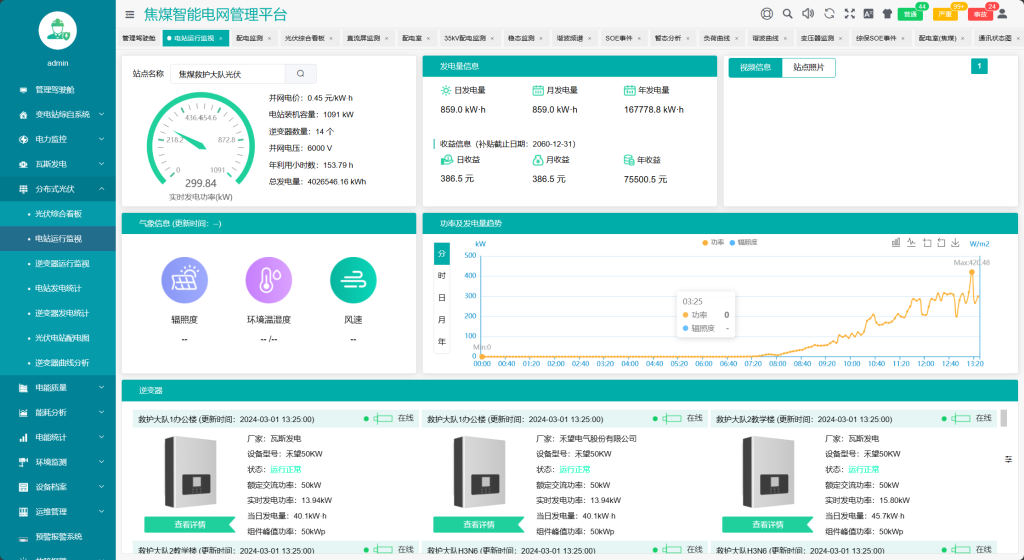

The Jiaozuo Mining District's power grid energy efficiency management platform divides the company's electricity consumption into source, grid, and operation and maintenance planning. It can monitor and display the company's entire electricity consumption in a single system. Numerous subsystems are no longer required, making it easier for managers to better manage the company.

Project content

The first phase of the project includes 19 substations, 1 gas-fired power plant and 1 photovoltaic power plant.

Zhaogu 1# 110 kV substation: Install power quality and arc protection devices to upload data to the EMS platform. At the same time, all telemetry and telesignal data from Sifang microcomputer protection and other power systems at the site are forwarded to the communication management machine in the IEC104 protocol and uploaded to the EMS platform.

110 kV Fengying booster station and other substations: Forward all telemetry and telesignal data of the power system of the NARI system site to the communication management machine and upload them to the EMS platform.

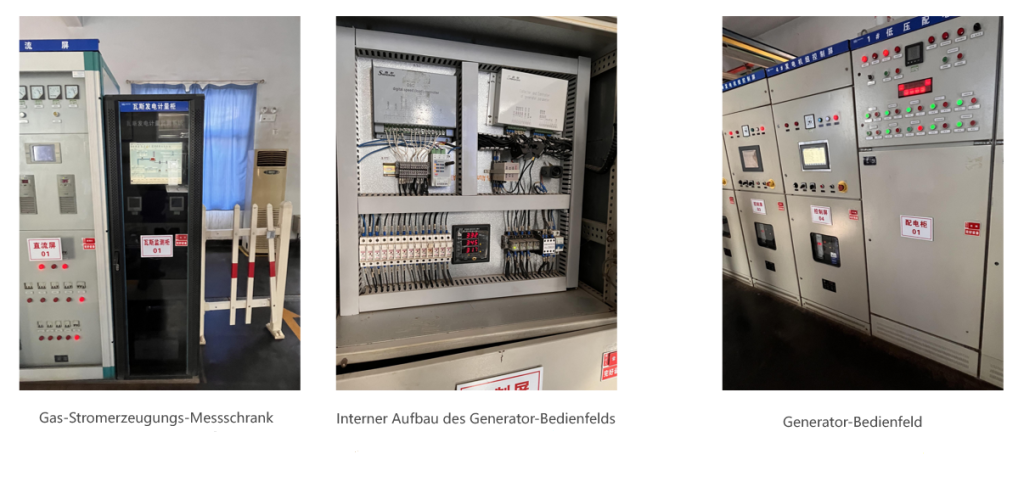

Gas power plant: Forward data to the communication management machine through the PLC system background and upload it to the EMS platform to monitor the generator set status in real time and count power generation.

Photovoltaic power plant: Install a gateway to monitor the working status and power generation of the inverter, display real-time data on the AC and DC sides, and update the power data in real time with fast response.

The platform is connected to the video surveillance and line inspection of substations, gas-fired power plants and photovoltaic systems.

Send EMS fault alarm information to the coking coal early warning platform.

Project location

Photos of the project renovation on site

Phase II planning

Personalized dashboard

Based on the on-site situation, all data overviews are displayed on a uniform interface.

Video access

Designed for corporate videos or large video producers, a unified platform is used to enable preview, playback or control.

Gas-fired power plant

A total of 14 units were integrated into three gas-fired power plants and further developed on the basis of the original local system, connected to the gas power generation data and managed uniformly.

Photovoltaic power plant

2 projects with 19 locations and 39 Sungrow inverters

Substation environment

Temperature and humidity monitoring and installation of a fire protection system for 19 substations

2.5D diagram

Create detailed and realistic graphic presentations faster while controlling costs.